A global supplier of specialty rubber seals and shock absorbers.

Strong manufacturing and R&D capabilities.

More than 30 years of R&D and manufacturing experience.

Views: 0 Author: Site Editor Publish Time: 01-29-2026 Origin: Site

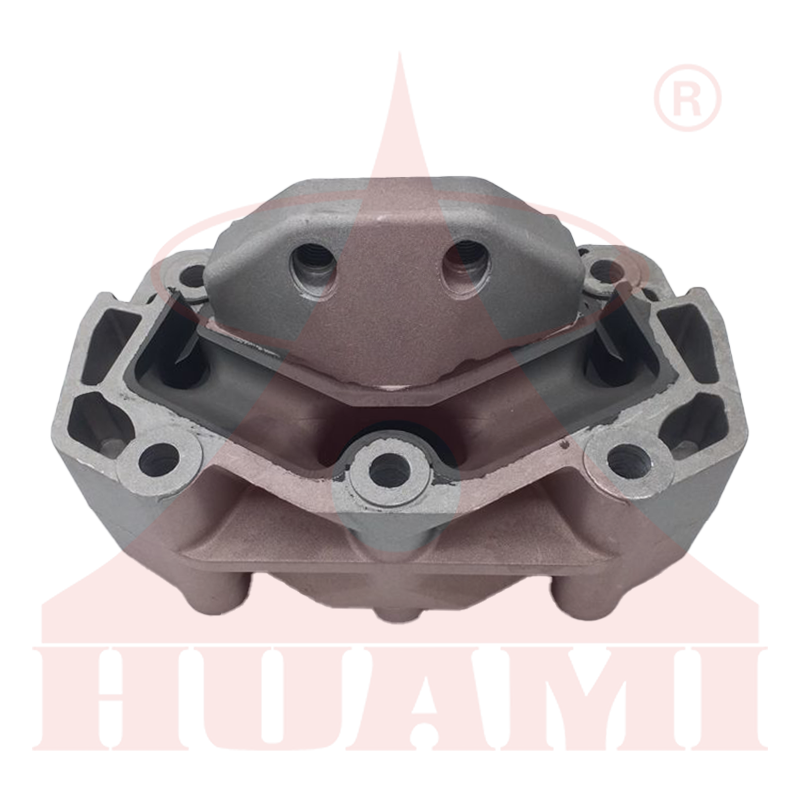

For long-haul, heavy-load Scania operations, the engine mount is not just a “support part”—it is a critical NVH component that directly affects powertrain reliability, comfort, and vehicle service life. This article focuses on the Scania truck engine mount, explaining the compatibility between OEM 1336882 and 1371725 replacement, structure and materials, failure symptoms, installation and maintenance, and how to choose the right supplier—helping distributors, repair shops, and fleet buyers make fast, correct decisions.

An engine mount (Rubber-Metal Engine Mount) is usually installed between the engine and the frame/subframe. It is the core “positioning + vibration isolation” component of the powertrain. For heavy-duty vehicles like Scania trucks, it mainly performs the following functions:

The engine and gearbox form a heavy, high-inertia powertrain. The metal bracket provides load-bearing and positioning, ensuring stable force paths in longitudinal, lateral, and vertical directions and preventing cumulative displacement during acceleration, braking, and rough-road impacts.

Combustion pulses, torque fluctuations, and driveline meshing generate periodic vibration, while potholes, speed bumps, and gravel roads create random shocks. High-damping rubber dissipates vibration energy through deformation and internal friction, significantly reducing vibration transmitted to the cab and frame.

The engine mount is the first isolation barrier in the NVH chain. When mount performance degrades, cab shake, low-frequency resonance, and abnormal noise often appear first. A well-designed mount balances low-frequency idle comfort with mid-to-high-speed stability, making the truck feel more stable and quieter.

In long-haul, heavy-load, high-temperature, or frequent start-stop conditions, the mount is subjected to cyclic loads and thermal cycling. Insufficient performance may cause:

Powertrain attitude changes → abnormal driveshaft angles and accelerated universal joint wear

Exhaust and pipelines overstressed → higher risk of flexible joint fatigue and cracking

Abnormal stress on bolts and brackets → loosening, noise, and secondary damage

Therefore, selecting a durable mount with reliable bonding and material matched to the duty cycle is essential for fleet TCO (total cost of ownership).

1336882: common formats include 1336882, 1 336 882, OE 1336882

1371725: common formats include 1371725, 1 371 725, OE 1371725

For sourcing and search, use keyword combinations such as:

“1336882 engine mount Scania”, “1371725 replacement”, “Scania truck engine mount”.

In the aftermarket supply chain, 1371725 replacement is often used to correspond to/replace certain versions of 1336882 (or revised/updated numbers used by different supply systems). Final fitment should still be confirmed by:

Vehicle model/chassis number, engine type, model year range

Mounting hole positions, overall dimensions, limit-stop structure

Rubber hardness and dynamic stiffness requirements (NVH matching)

Recommended practice: fleets/repair shops verify by measuring the old part or OEM data; distributors verify by EPC/cross-reference and drawing comparison.

Scania powertrains deliver high torque and complex vibration excitations, requiring:

Load capacity and dynamic stiffness matched to heavy-duty torque fluctuations

Damping that balances idle comfort and high-speed stability

Durable bonding and fatigue resistance for long mileage operation

Depending on vehicle structure, mounts may be:

Front / rear mounts: control powertrain pitch and longitudinal movement

Left / right side mounts: control lateral swing and side loads

Mounts with limit-stop structures: restrict extreme displacement during large impacts

The exact installation position should be confirmed by the specific vehicle and original part design.

A typical Rubber-Metal Engine Mount consists of:

Metal bracket/inner-outer shells: load-bearing, positioning, bolt load transfer

Rubber elastomer: vibration isolation, damping, shock buffering

Bonding layer and adhesive system: determines rubber-to-metal bonding strength and lifetime ceiling

Hebei Huami can provide compound solutions based on operating conditions:

NR (Natural Rubber): high elasticity, excellent fatigue resistance, good for general isolation

NBR (Nitrile Rubber): stronger oil resistance, suitable for oily environments or oil mist exposure

EPDM: outstanding weather/ozone/aging resistance, suitable for temperature swings and outdoor exposure

Material selection should be based on temperature, oil exposure, salt spray, load spectrum, and NVH targets.

Hardness is not “the higher the better.” A common range is Shore A 55–80 (customizable):

Lower hardness: softer isolation, but may reduce load/attitude control

Higher hardness: more stable attitude, but may transmit more vibration and increase low-frequency resonance

Huami supports balancing hardness/damping/dynamic stiffness for specific vehicles and duty cycles.

Heavy-duty engine bays are hot, oily, and cyclically loaded, so the compound system must balance:

Heat aging resistance: reduce hardening and cracking

Oil/medium resistance: minimize swelling and property drift

Fatigue and tear resistance: delay crack growth

Weather/ozone resistance: adapt to outdoor and temperature cycling

Typical options include:

E-coating/powder coating/Dacromet/zinc plating, etc. (as required)

Surface roughening and primer systems to improve bonding reliability

For salted or wet-road regions, corrosion level directly impacts service life and maintenance cost.

A common failure is debonding. Key factors include:

Metal pretreatment (cleanliness, roughness, activation)

Adhesive system matching (primer/topcoat stability)

Vulcanization curve control (temperature, time, pressure)

Process consistency (batch variation, mixing uniformity)

Huami ensures bonding strength and batch consistency through compound R&D and process control.

When a Scania truck engine mount ages or is damaged, typical symptoms include:

Increased low-frequency vibration in the steering wheel, seat, or cab at idle often indicates reduced isolation or shifted dynamic stiffness.

Insufficient attitude control amplifies torque reaction, causing harsher launch and more pronounced shift shock.

Increased compression set can cause the engine to sit lower or shift, leading to metal contact or abnormal noise.

Visible cracking, tearing, or separation between rubber and metal. In such cases, replacement is recommended to avoid secondary damage.

Visual check for cracks, debonding, oil attack

Light prying to observe displacement and rebound

Road test for launch/shift shock and abnormal noises

Compare idle vibration level with a normal vehicle of the same model

If debonding or significant attitude abnormality is present, continued heavy-duty operation is not recommended.

Use reliable supports to hold the engine/gearbox to prevent sudden load drop during removal

Check related fasteners, brackets, and seats for damage or deformation

Clean mounting surfaces to ensure correct positioning and tightening

Mark mount orientation and locating points (avoid incorrect installation)

Gradually transfer powertrain weight to the support

Remove the old part; inspect seats and holes for wear

Install the new mount and pre-tighten for positioning

Restore the powertrain attitude; confirm no interference

Tighten in steps to the specified torque

Observe idle vibration and abnormal noise elimination

Test launch, light acceleration, and shifting to verify reduced shock

Check for interference with exhaust, lines, fan, etc.

Recheck critical fastener tightness as required by process

Reduce long-term oil soaking (fix leaks promptly)

Periodically check surrounding fasteners and bracket cracks

Avoid high-speed impacts on rough roads while overloaded

Fleets can implement a “mileage + duty cycle” replacement strategy to reduce unexpected failures

When choosing a Scania engine mount supplier, beyond price, focus on compound & bonding durability, batch consistency, and validation capabilities. Hebei Huami New Material Technology Co., Ltd. offers:

30 years of rubber products and rubber-metal component manufacturing experience

Experience covering Scania and multiple heavy-duty truck brands with fitment and replacement development support

Systems & qualifications: IATF16949, TÜV-related certifications, and Customs AEO Advanced Certification for quality and international delivery assurance

Independent compound R&D capability: high-damping, durable, heavy-load reinforced engine mount solutions (NR/NBR/EPDM options)

Precision tooling and automated production: stable processes and higher batch consistency for long-term supply

Full-process QC: hardness / tensile / tear / compression set / bonding strength

Reliability tests: oil resistance, heat aging, salt spray, high-low temperature, fatigue life (as required)

OEM/ODM and small-batch customization: drawing/sample-based development, low MOQ, fast prototyping, and stable lead times

Inquiry tip: provide OEM number (1336882 / 1371725), vehicle info, and photos/dimensions/drawings for quick fitment confirmation and material recommendation.

The following are common inquiry and documentation fields. Final specs depend on drawings/samples and vehicle confirmation.

| Item | Specification / Notes |

|---|---|

| Product Name | Scania Truck Engine Mount (Rubber-Metal Engine Mount) |

| OEM Numbers | 1336882 / 1371725 (replacement) |

| Applicable Vehicle | Scania Trucks (fitment & location subject to vehicle confirmation) |

| Installation Position | Front/rear/left/right engine mount (confirm by vehicle structure) |

| Overall Dimensions (L×W×H) | TBD (OEM standard or customized by drawing/sample) |

| Rubber Material | NR / NBR / EPDM (optional, matched to duty cycle) |

| Hardness (Shore A) | 55–80 (customizable for NVH & load balance) |

| Metal Treatment | E-coating / zinc plating / powder coating, etc. (as required) |

| Key Process | Vulcanized rubber-to-metal bonding, focus on adhesion durability |

| Packaging | Neutral packing / customized packing (TBD) |

| MOQ | Low MOQ (TBD, subject to inquiry) |

| Delivery | Fast sampling, stable lead time for mass production (negotiable) |

Q1: Can 1336882 and 1371725 be used interchangeably?

A: In the aftermarket supply chain, 1371725 replacement commonly corresponds to/replaces some 1336882 applications. Final interchangeability should be confirmed by vehicle details, mounting geometry, dimensions, and NVH requirements.

Q2: How do I confirm fitment for a specific Scania truck?

A: Provide the OEM number plus vehicle details (chassis number/engine type/model year) or compare the original part with technical drawings for the most reliable confirmation.

Q3: What are the most typical symptoms of a failed engine mount?

A: Increased idle vibration, stronger shock during launch/acceleration/shifting, abnormal noise, engine sag/misalignment, and visible rubber cracking or debonding.

Q4: Does higher Shore A hardness mean longer service life?

A: Not necessarily. Hardness affects the balance between vibration isolation and load control. Proper selection should match duty cycle and NVH targets.

Q5: How should I choose between NR, NBR, and EPDM?

A: NR offers strong elasticity and fatigue resistance; NBR provides better oil resistance; EPDM offers superior weather/ozone aging resistance. Selection depends on temperature, oil exposure, and environment.

Q6: Why does rubber-to-metal debonding occur?

A: Debonding is highly related to metal pretreatment, adhesive system matching, vulcanization parameters, and process consistency. Controlled bonding is critical to service life.

Q7: What safety precautions are required during replacement?

A: Safely support the powertrain before removal, keep mounting surfaces clean, and tighten fasteners to the specified torque using a torque wrench.

Q8: What is the typical service life of an engine mount?

A: Service life depends on load, road conditions, temperature, oil exposure, and driving habits. Fleets should implement mileage-based inspections; replace promptly when cracks or debonding appear.

Q9: Do you support low MOQ and customization?

A: Yes. We support OEM/ODM, drawing/sample-based development, low MOQ, fast prototyping, stable lead times, and QC documentation.

Volvo Truck Air Spring OEM 20531987 Selection, Structure & Replacement Guide

Mercedes-Benz Truck Leaf Spring Bushing (OEM 6733200050) Front Axle Selection & Replacement Guide

Scania Truck Engine Mount OEM 1336882 / 1371725 Replacement & Selection Guide

HINO Truck Torque Rod Bushing — OEM 55541-00Z00 Selection & Replacement Guide