A global supplier of specialty rubber seals and shock absorbers.

Strong manufacturing and R&D capabilities.

More than 30 years of R&D and manufacturing experience.

Views: 0 Author: Site Editor Publish Time: 01-19-2026 Origin: Site

An engine mount is not just a “mounting bracket”—it is a critical component for powertrain reliability and ride comfort. For HINO trucks, engines often operate under heavy loads, long duty cycles, frequent stop-and-go, and repeated heat/cool cycles. The engine mount directly affects:

The engine mount supports and locates the powertrain on the chassis, keeping the relative position between the engine, transmission, driveline and surrounding systems stable—helping prevent hose/pipe tension, interference wear, and misalignment.

At idle, acceleration, gear shifts and climbs, the engine produces vibration across multiple frequency bands and torque reactions. The rubber damping body deforms elastically and dissipates energy through internal damping, reducing vibration transfer to the frame and cab.

A high-quality engine mount noticeably reduces steering wheel/seat/pedal buzz, lowers cab resonance, and helps prevent squeaks and rattles—improving driver comfort and safety on long-haul routes.

Truck “reliability” is often about details: once engine mount performance declines, powertrain movement increases, which can trigger a chain of issues such as exhaust/intake fatigue, coolant hose leaks, belt system mis-wear, and bracket cracking, leading to higher downtime and maintenance costs.

Common formats you may see include:

12371-E0150

For sourcing and search accuracy, use combinations like “12371-E0150 engine mount” and “HINO truck engine mount”.

HINO trucks typically emphasize durability and stability, so engine mounts must combine load support with vibration isolation. Engine mounts like 12371-E0150 generally need to deliver:

Multi-axial load handling (vertical support + longitudinal/lateral control)

Balanced performance for idle isolation and acceleration torque shock resistance

Oil resistance, heat-aging resistance, and fatigue durability

An engine mount may be located as:

Front / rear mount (controls longitudinal powertrain posture)

Left / right mount (primary load-bearing and lateral control)

Because layouts vary by model/year, we recommend confirming by mounting photos, old-part measurement, drawings, or samples

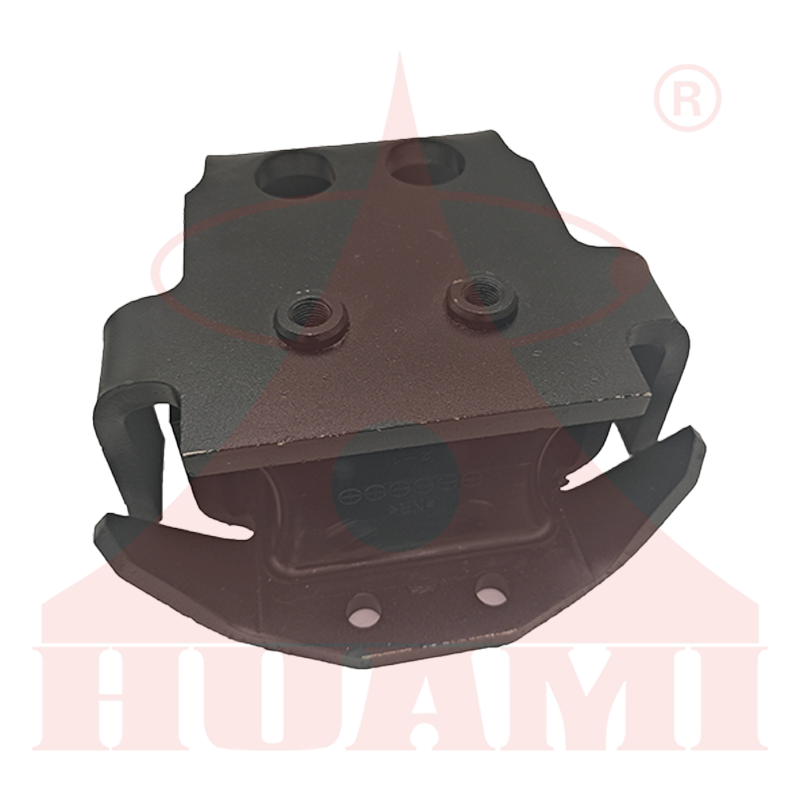

A typical Rubber-Metal Engine Mount consists of:

Metal bracket/skeleton: provides stiffness, mounting geometry, and load transfer path

Rubber damping body: provides elasticity and damping, and is integrated with metal through vulcanized bonding

Hebei Huami can select or compound materials based on operating conditions and customer requirements:

NR (Natural Rubber): excellent rebound and dynamic performance, ideal for high isolation needs

NBR (Nitrile Rubber): strong oil resistance, suitable for oil-exposure environments

EPDM: better heat-aging and ozone resistance, suitable for harsher thermal/environmental aging

Final selection depends on temperature, oil media, dynamic load frequency, and target lifetime.

Typical hardness ranges for engine mounts can cover Shore A 45–80 .

Lower hardness: better isolation, but may reduce impact resistance and shape stability

Higher hardness: stronger load and shock resistance, but may reduce isolation

Huami optimizes compound and structure together to balance isolation and durability for heavy-duty operation.

Engine bay environments involve heat sources, oil mist, water/mud, and salt exposure. A robust engine mount requires:

Heat-aging resistance to reduce hardening and cracking

Controlled oil swell to prevent dimension changes and bonding failure

Dynamic fatigue life to resist crack initiation and propagation under cyclic loads

To enhance anti-corrosion capability, options include coating, zinc plating/electroplating, phosphating, etc., reducing rust-related strength loss and assembly issues.

Rubber-to-metal bonding strength directly determines the risk of “debonding failure.” A mature surface treatment + bonding system + vulcanization curve control significantly improves long-term durability and batch consistency—core for engineering-grade engine mounts.

When the following symptoms appear, a HINO engine mount replacement inspection is often recommended:

Noticeable vibration at idle or while driving: stronger cab/steering wheel/pedal vibration

Stronger shock during start, acceleration, or shifting: harsher “thump” or driveline shock

Engine sag or misalignment: abnormal powertrain posture and clearance changes

Rubber aging, cracking, debonding: visible cracks, separation, or delamination

Abnormal noise: more obvious on rough roads or during hard accel/decel

Visual inspection: cracks, bulges, debonding, severe corrosion

Symptom reproduction: idle in gear / launch / shift shock behavior

Movement observation: under safe conditions, check whether torque reaction displacement is excessive

Compare with a healthy vehicle of the same model when possible, or confirm with professional technicians to avoid misdiagnosis.

Park safely, apply parking brake, use wheel chocks if needed

Use appropriate jacks/stands to safely support the powertrain

Avoid direct lifting on weak points such as the oil pan; use proper pads to distribute load

Mark original mount position and any shims/limit structures

Gradually unload mount stress (support first, then loosen fasteners)

Remove the old part and inspect related items (bolts, brackets, interference, hoses)

Install the new mount and pre-tighten step-by-step in a balanced sequence

Release support load and recheck alignment/clearances

Idle check: vibration improvement and abnormal noise

Road test: launch/accel/shift shock reduction

Re-torque check: follow specifications if a secondary check is required

Control oil leaks: oil exposure can accelerate compound deterioration

Avoid chronic overloading and aggressive driving: shock peaks reduce fatigue life

Periodic inspection: fleets can implement preventive schedules to reduce downtime

As a global truck engine mount supplier, Hebei Huami New Material Technology Co., Ltd. offers verified capabilities for heavy-duty rubber-metal components:

30 years of experience in rubber products and rubber-metal components

Serving high-reliability sectors: commercial vehicles, construction machinery, high-speed rail, aerospace, etc.

Systems & certifications: IATF16949, TÜV certification, AEO Advanced Certification

In-house rubber compound R&D: high damping, durable, reinforced mounts for heavy-duty duty cycles

Precision tooling and automated production: stable mass consistency for long-term supply

Full-process quality inspection: hardness / tensile / tear / compression set / bonding strength

Validation capability: oil resistance, heat aging, salt spray, high/low temperature, fatigue life tests

OEM/ODM and small-batch customization support: drawing/sample development, stable lead time

If you are sourcing a stable supply for HINO truck engine mount (12371-E0150) and need customization or development support, share photos, mounting information, drawings, or a sample for fast technical evaluation and quotation.

| Item | Specification / Notes |

|---|---|

| OEM Number | 12371-E0150 |

| Product Name | HINO Truck Engine Mount / Rubber-Metal Engine Mount |

| Rubber Material | NR / NBR / EPDM (customizable) |

| Hardness (Shore A) | 45–80 (customizable; tuned for isolation & load target) |

| Metal Surface Treatment | Coating / Plating (optional) |

| Vehicle Fitment | HINO Trucks (year & position to be confirmed by OE catalog) |

| Mounting Position | Front / Rear / Left / Right (depends on vehicle layout) |

A: 12371-E0150 is used as a HINO truck engine mount to support the powertrain, control movement, and reduce vibration transfer to the frame/cab.

A: Confirm by VIN/OE catalog, installation position, and comparing dimensions & hole spacing. Sharing photos or an old sample helps ensure accuracy.

A: Increased vibration at idle, stronger shock during start/shift, engine sag/misalignment, visible rubber cracks, or rubber-to-metal separation.

A: Common options include NR, NBR, EPDM. Selection depends on temperature, oil exposure, and durability targets.

A: Hardness typically ranges 45–80 Shore A. Softer improves isolation; harder improves load & impact resistance. We tune hardness with structure and compound.

A: Yes. We support OEM/ODM, prototype sampling, and low MOQ options depending on the project scope.

A: Through controlled metal surface treatment + adhesive system + vulcanization process, plus bonding strength inspection and durability validation.

A: Hardness, tensile/tear, compression set, bonding strength, plus optional oil resistance, heat aging, salt spray, low/high temp, fatigue life tests.