Views: 0 Author: Site Editor Publish Time: 01-24-2026 Origin: Site

Under heavy-duty, long-haul, and high-frequency start-stop operating conditions, suspension and chassis bushings directly affect vehicle stability, ride comfort, and tire life. This article focuses on Volvo truck bushing 9959304 (replacement: 3028448 / 9516523 / 1137960 / 1193034), and explains—systematically—the functional role, structure and materials, failure diagnosis, installation/maintenance, and purchasing points, helping distributors, repair shops, and fleet buyers make fast and correct decisions.

Truck chassis components experience continuous impacts from roads and loads. Rubber-metal bushings dissipate energy through rubber shear deformation and damping, filtering high-frequency vibration at joints between links and the frame, thereby:

Reducing resonance transmitted to the cab and body for improved comfort

Minimizing fatigue damage to metal parts caused by high-frequency impacts

Maintaining more consistent handling feedback on rough roads

A bushing is not only “soft”—it must also be “precise.” While allowing controlled elastic movement, it restrains the motion path of link rods/control arms to ensure:

More stable axle geometry (less pulling and shimmy)

More consistent steering response and better control during braking

More uniform tire contact, reducing irregular wear and cupping

If metal parts contact directly, tiny clearances become amplified as noise and wear. Bushings:

Isolate metal contact to reduce friction and knocking

Suppress clearance growth and prevent increasing “looseness”

Lower the chance of secondary damage to links, brackets, and axle joints

Typical commercial vehicle conditions (near-limit loads, downhill braking, large temperature swings, rain/snow/salt fog) accelerate rubber aging and bonding fatigue. Poor bushing condition leads to unstable steering, abnormal tire wear, and braking wander, increasing operating costs and safety risks. That’s why choosing the right rubber metal bushing for Volvo truck and installing/maintaining it correctly is a long-term strategy for both savings and safety.

OEM: 9959304

Common formats: 9959304 / 99 593 04 (format may vary by system)

Purchasing tip: confirm with OE number + dimensions/structure drawing to avoid misfitment due to number-only matching.

In aftermarket and supply chain references, 9959304 may be cross-referenced with the following numbers (final fitment depends on model year and position):

9959304 replacement: 3028448 / 9516523 / 1137960 / 1193034

For faster confirmation, provide: OE number, truck model/year, fitting position, and photos/dimensions of the removed part.

Volvo chassis joints typically face higher alternating loads and shear stresses. The bushing must balance “load stiffness” and “damping isolation,” while ensuring stable bonding and fatigue resistance. A qualified 9959304-type bushing generally offers:

Stiffness tuned for heavy-duty duty cycles (no collapse, no excessive harshness)

Reliable rubber-to-metal bonding and corrosion protection

Good tolerance to oil contamination, rain/snow, and temperature cycling

Fitting positions vary by model and chassis design. Based on the parameters you provided, this bushing can be used at:

Fitting Position: Front Axle Both Sides

Common applications: front axle joint positions on suspension link rods/control arms (final confirmation by actual truck configuration).

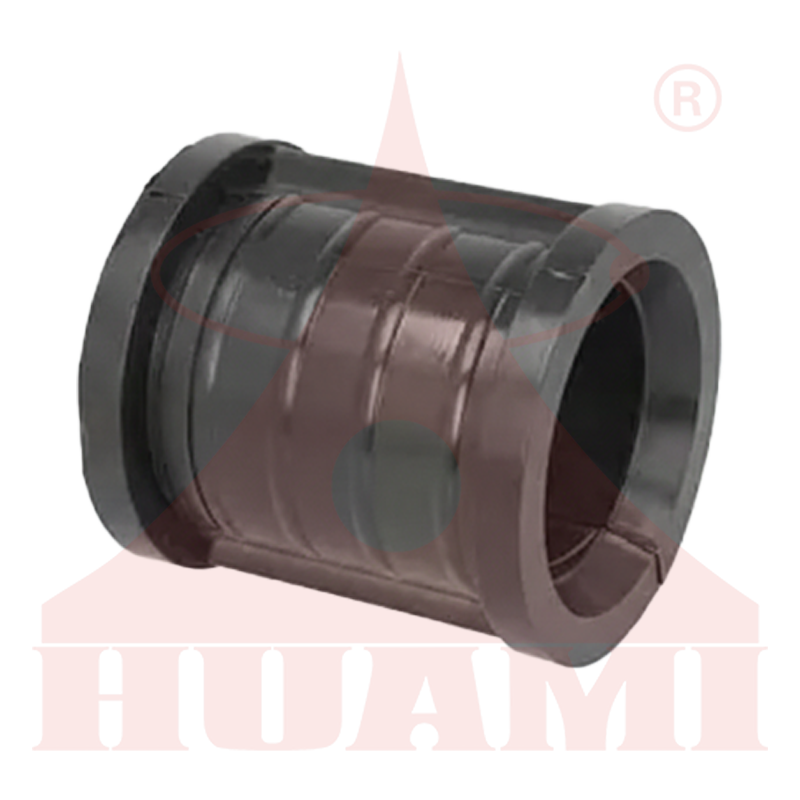

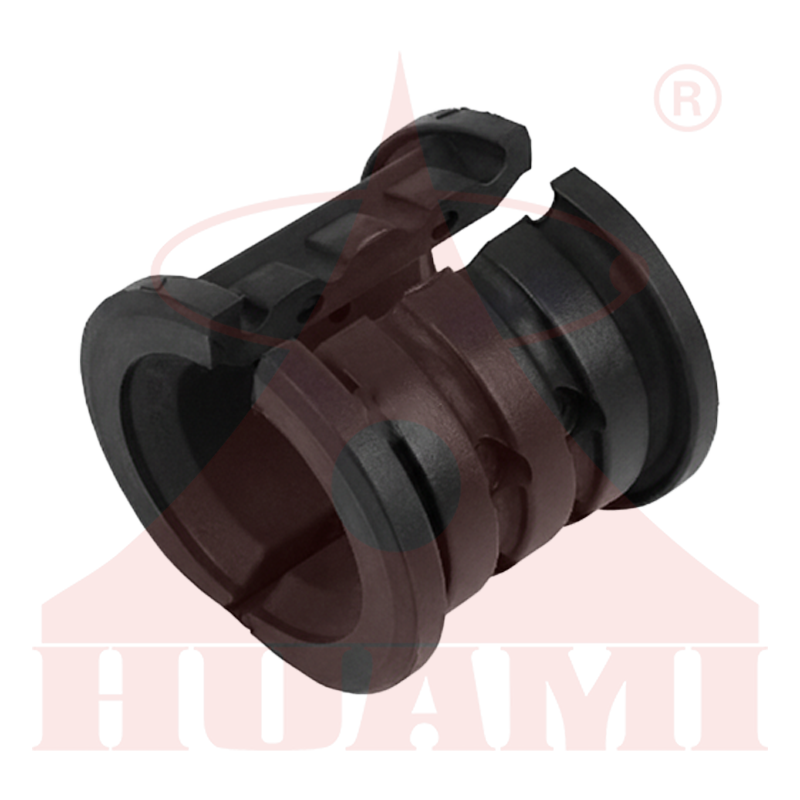

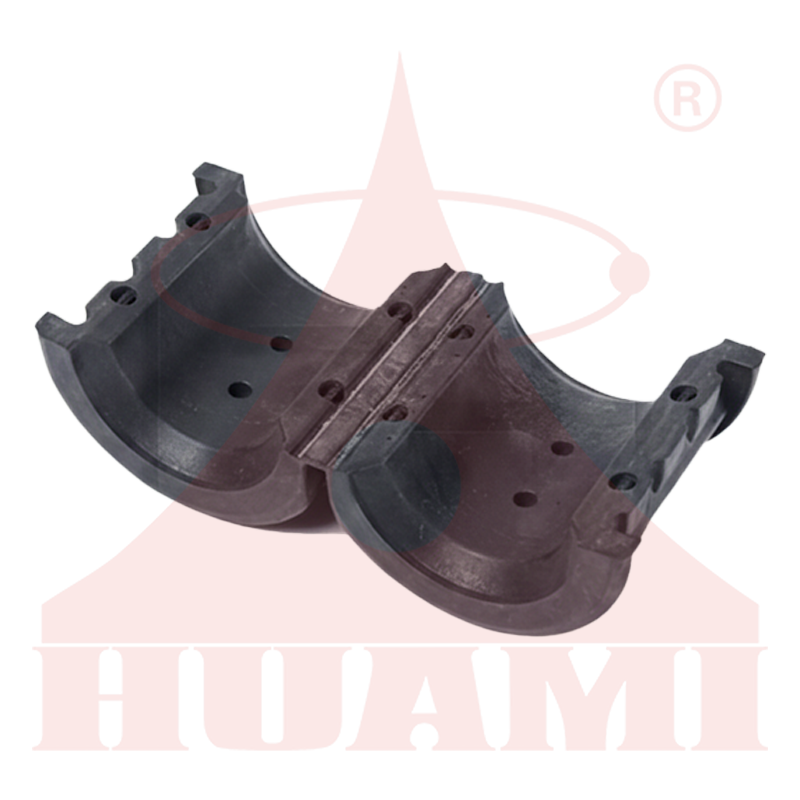

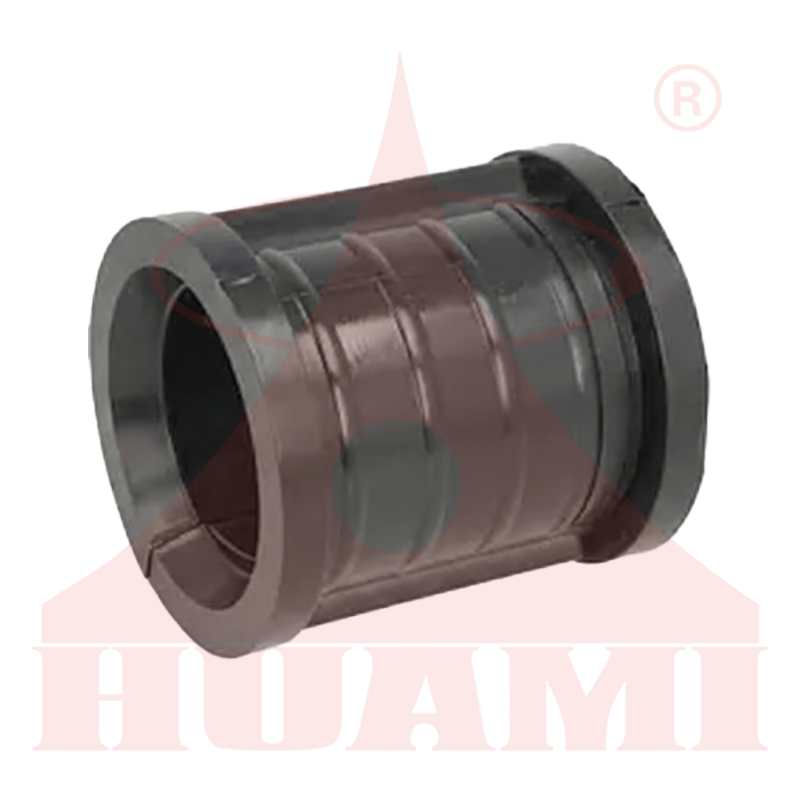

A typical rubber-metal bushing consists of:

Inner steel sleeve: provides bolt clamping and positioning reference

Outer steel sleeve: mates with housing/bore and takes press-fit stress

Rubber elastomer: performs shear deformation, damping, and isolation

Structural design directly impacts press-fit stability, off-axis load capability, and service life.

Hebei Huami New Material can select and optimize compounds by duty conditions (examples):

NR (Natural Rubber): excellent elasticity and fatigue performance for durability

NBR (Nitrile Rubber): stronger oil resistance for oily environments or near powertrain/driveline

EPDM: strong weathering and ozone resistance for wide temperature swings and outdoor exposure

A typical design targets a certain Shore A range (customizable). In principle:

Higher hardness: better load control and stability, potentially less isolation

Lower hardness: better comfort, but may deform/heat up under heavy loads and braking shocks

A professional Volvo suspension bushing supplier will recommend hardness based on the duty cycle to achieve “durability + stability.”

For commercial vehicle bushings, the priorities include:

Fatigue resistance: prevents crack initiation and growth under alternating loads

Shear resistance & low permanent set: reduces looseness and geometry drift

Oil & weather resistance: withstands contamination, salt fog, moisture, and temperature cycles

In exposed or humid environments, corrosion protection affects press-fit zones and bonding edges. Typical options:

Protective coating (painting)

Plating/passivation (improved salt-spray performance)

A significant share of bushing failures come from debonding and bonding fatigue. Stable vulcanization bonding and process control (temperature, time, cleanliness, bonding system match) can greatly improve life and batch consistency—core capabilities to evaluate when choosing a Volvo suspension bushing supplier.

“Clunking” over speed bumps or potholes

Increased fine vibration in steering wheel or cab at speed

Noticeable fore-aft “nodding” or sway on take-off/braking

Visible abnormal movement or increased play at the joint

Needs continuous steering correction in a straight line

Irregular wear, saw-tooth wear, or localized overheating

Surface cracking, chalking/powdering

Separation at rubber-metal interface, gaps, or tearing

Visual inspection: cracks, debonding, powdering, eccentric deformation

Pry bar check: abnormal looseness under leverage

Road test comparison: changes under different loads and road conditions

Tire wear and alignment data: repeated alignment drift often points to bushing/joint issues first

Use a hydraulic press and proper tooling—avoid hammering that deforms sleeves

Ensure the bore is clean and free of burrs and rust

If lubricant is needed, use rubber-compatible assembly media; avoid oils that may attack the compound

Some bushings are directional (slots/eccentric designs). Always:

Press-fit according to OE marks or tooling references

Ensure concentricity between inner/outer sleeves to prevent early tearing from side loads

Avoid prolonged overload and high-speed impacts on rough roads

Fix oil leaks and remove mud/sand buildup and corrosion early

Link chassis servicing with alignment checks to prevent “run-to-fail” damage escalation

30 years of rubber products and rubber-metal manufacturing experience: wide coverage of bushings, mounts, and vibration-damping parts

Multi-industry service capability: commercial vehicles, construction machinery, and high-speed rail require high durability and consistency

System & compliance certifications: IATF16949, TÜV certification, and AEO Advanced Certification for international supply chain readiness

In-house compound R&D: heavy-duty, oil-resistant, weather-resistant, low-temperature solutions as needed

Precision tooling and automated production: batch consistency and traceability

Full-process quality inspection: hardness / tensile / tear / compression set / bonding strength

Reliability validation: salt spray, oil resistance, weathering, high/low temperature, and fatigue life testing

OEM/ODM and small-batch customization: drawing/sample-based customization with stable lead times

| Item | Specification / Notes |

|---|---|

| Product Name | Volvo Truck Rubber-Metal Bushing |

| OEM | 9959304 |

| Replacement OEM | 3028448 / 9516523 / 1137960 / 1193034 |

| Fitting Position | Front Axle Both Sides |

| Outer Diameter 1 (OD1) | 78 mm |

| Outer Diameter 2 (OD2) | 91 mm |

| Inner Diameter (ID) | 50 mm |

| Length (L) | 95 mm |

| Structure | Inner steel sleeve / Outer steel sleeve / Rubber elastomer |

| Rubber Materials | NR / NBR / EPDM (customizable) |

| Metal Surface Treatment | Coating / Plating (optional) |

| Applicable Vehicle | Volvo Trucks (confirm by model/year and position) |

| Packing | Neutral Packing |

| MOQ | Low MOQ |

Q: What are the dimensions of OEM 9959304?

A: The specification is OD1 78mm, OD2 91mm, ID 50mm, length 95mm, with fitting position on the front axle both sides.

Q: Which part numbers are commonly used as 9959304 replacement?

A: Common cross references include 3028448, 9516523, 1137960, and 1193034 (confirm by model/year and position).

Q: What symptoms indicate a worn front axle bushing?

A: Clunking noise, unstable steering, increased vibration, abnormal tire wear, and looseness are typical signs.

Q: What are the most common installation mistakes?

A: Off-center press-fit, not cleaning rust/burrs, hammering instead of pressing, and not final-tightening at normal ride height.

Q: Why tighten at normal ride height?

A: It prevents rubber pre-twist, reducing heat build-up and tearing risk, improving durability.

Q: How should I choose NR/NBR/EPDM?

A: NR is often preferred for heavy-duty fatigue durability, NBR for oily environments, and EPDM for strong weathering/ozone resistance—customizable by duty cycle.

Q: Do you support neutral packing?

A: Yes, neutral packing is available, and custom packing can be supported on request.

Q: Can MOQ be low?

A: Yes, low MOQ is supported depending on tooling and stock status.

Q: How can I ensure perfect fitment for my truck?

A: Provide the OE number, model/year, fitting position, and photos/dimensions of the removed part for fast confirmation and sampling advice.