A global supplier of specialty rubber seals and shock absorbers.

Strong manufacturing and R&D capabilities.

More than 30 years of R&D and manufacturing experience.

Views: 0 Author: Site Editor Publish Time: 01-20-2026 Origin: Site

An engine mount is a critical component that connects the powertrain (engine + transmission) to the chassis/subframe. For heavy-duty trucks such as Volvo FH / FM / FMX, operating under high torque, heavy loads, and long duty cycles, the engine mount is not just a comfort part—it is a structural and durability component that affects reliability and total cost of ownership.

The engine, transmission, and accessories form a high-mass assembly with large inertia. A rubber-metal engine mount works through a combination of metal structure and rubber damping element to:

Carry static load and keep correct engine height and alignment

Control dynamic movement during acceleration, braking, climbing, and shifting

Maintain driveline alignment, reducing misload on prop shafts, U-joints, and couplings

Heavy-duty engines generate multi-frequency vibration at idle and under low-speed high-torque conditions. Road impacts (potholes, rough roads, fully-loaded bouncing) further increase transient loads. A high-quality rubber-metal mount dissipates energy through rubber viscoelasticity:

Provides support against low-frequency, large displacement events (start-up/shifting shock)

Isolates mid-to-high frequency vibration (engine pulsation, structural resonance)

Buffers instant shocks from harsh road conditions and sudden torque changes

NVH is not only about comfort—it is a top aftermarket complaint driver:

Worn mounts cause cab shake, steering wheel vibration, and more noise

Excess powertrain movement increases stress fatigue on exhaust, boost pipes, coolant hoses

Long-term vibration accelerates wear on rubber parts, fasteners, brackets, and weld points

Fleet operators focus on lifecycle cost. Incorrect selection or inconsistent quality can lead to:

Frequent replacements and downtime losses

Secondary damage to driveline, exhaust system, and accessories

Increased claims and workshop rework rates

Primary OEM: 21416526

Replacement / equivalent: 7421416526 (also seen as 7421 416 526 in some catalogs)

Different ERP systems may insert spaces or segment digits. Final identification should be based on 21416526 / 7421416526.

In the aftermarket, 7421416526 engine mount replacement is commonly treated as a cross reference to 21416526. For accurate purchasing:

Confirm dimensions, mounting geometry, structural type, and hardness grade

The same physical part may be assigned different numbers across brand systems

Cross-brand compatibility typically comes from supply-chain realities:

Group/platform sharing across brands and powertrain architectures

Modular supplier design, covering multiple vehicles with tuning via compound/hardness

Aftermarket cross-OEM mapping, grouping interchangeable parts under reference chains

If you see Volvo FH FM FMX engine mount, Renault Trucks engine mount, and PSA/DS/Citroën/Peugeot compatibility together, the best practice is always: drawing/sample matching + key dimensions + hardness confirmation.

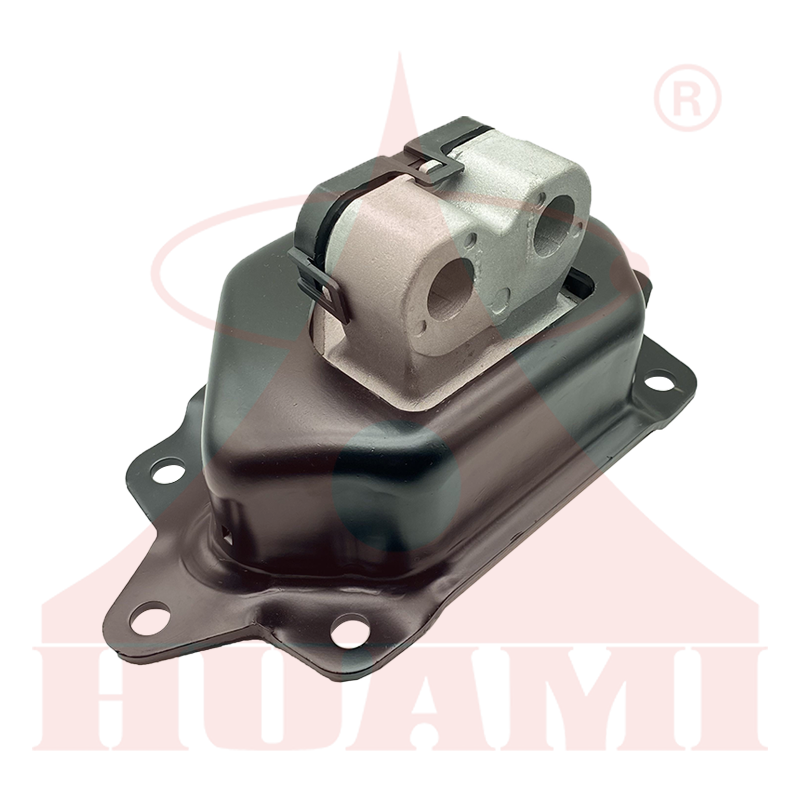

This type of rubber-metal engine mount is often installed as:

Left/right engine side mount

Front or rear powertrain support

Working together with transmission mount(s) as the complete “powertrain mounting system”

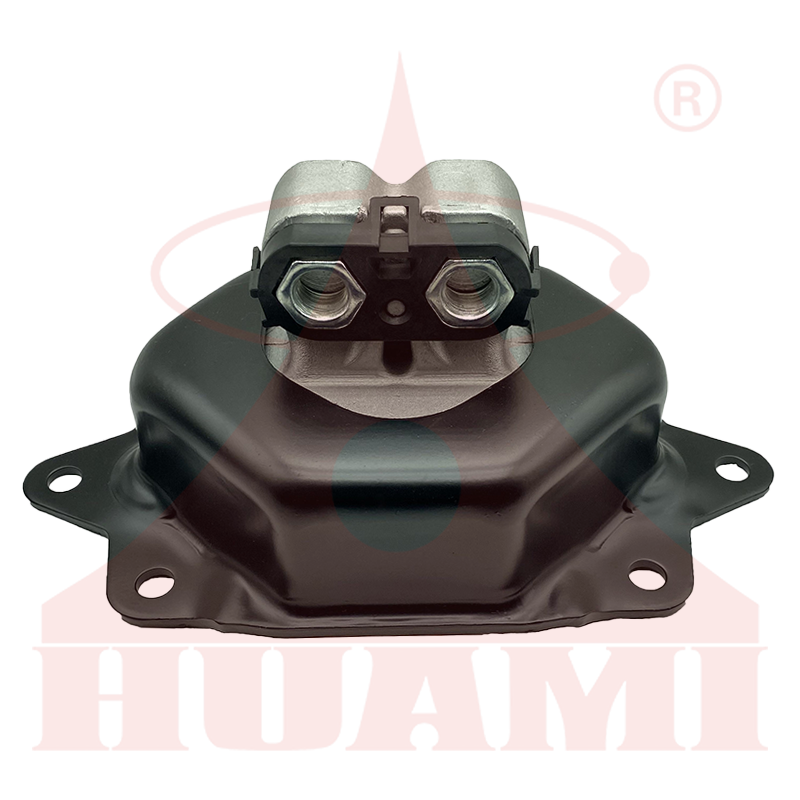

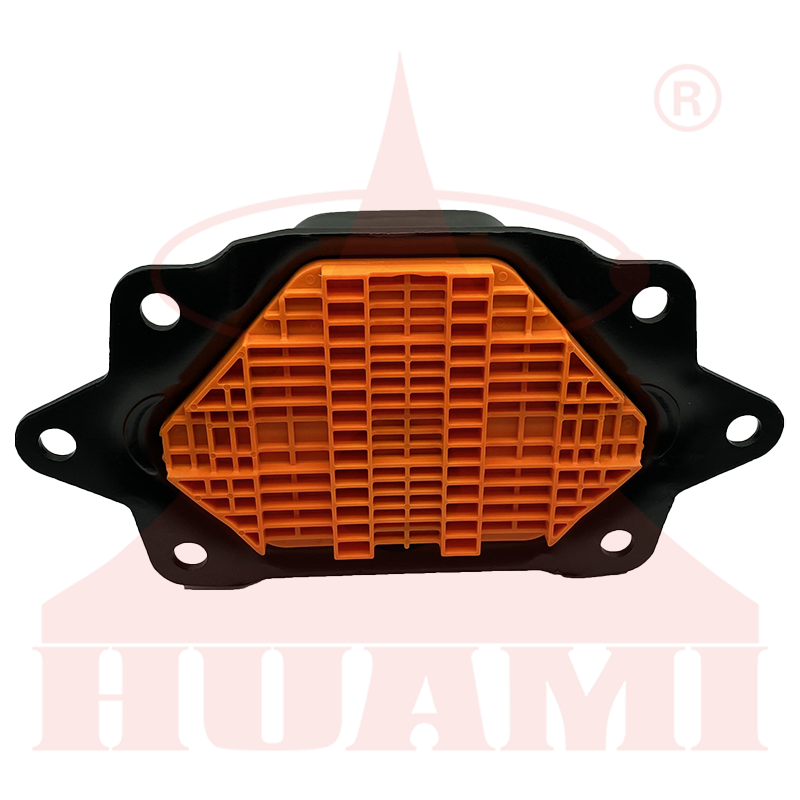

A typical rubber-metal engine mount consists of:

Metal components (housing/bracket/plates) for strength and mounting reference

Rubber damping core for isolation, cushioning, rebound, and durability

Good design balances load stiffness and isolation: too stiff increases vibration transfer; too soft increases powertrain displacement and harshness.

Depending on duty conditions, common rubber systems include:

NR (Natural Rubber): excellent dynamic properties and vibration isolation

NBR (Nitrile Rubber): superior oil resistance for oily environments

EPDM: strong heat/ozone/weather resistance for high-temperature aging conditions

In production, blended compounds are also used to balance isolation and resistance needs.

Typical hardness selection range (example): 55–75 Shore A (customizable).

Lower hardness: better isolation, but may allow larger displacement under torque

Higher hardness: stronger support, but more NVH transmission

Fleets usually prioritize stable load control + fatigue durability, while urban operations may favor comfort. Huami can tune both compound and structure to achieve the target balance.

Engine-bay heat, oil mist, salt spray, moisture, and long cyclic loads are major aging factors. A reliable compound should maintain:

Stable hardness after heat aging

Controlled swelling and stable bonding after oil exposure

Resistance to crack growth and permanent deformation under cyclic loading

Heavy-duty environments require corrosion control that supports both appearance and bonding durability:

Surface pretreatment (e.g., blasting/phosphating) for adhesion

Coating/e-coating/plating solutions per customer specification

Corrosion affects not only looks but also long-term bonding interface reliability.

Many mount failures originate from debonding rather than rubber bulk tearing. Service life depends heavily on:

Consistent metal surface preparation

Proper adhesive system selection

Stable vulcanization window control (temperature/pressure/time)

Hebei Huami New Material ensures durability through mature rubber-to-metal bonding and process control for stable batch consistency.

If you observe the following symptoms, inspect the engine mount first (especially for Volvo truck engine mount 21416526 positions):

Excessive vibration at idle or while driving (cab/seat/pedal vibration)

Harsher start-up, acceleration, or shifting impacts (amplified powertrain movement)

Engine sag, offset, or abnormal noise (metal contact or reduced rebound)

Rubber aging, cracking, or debonding (visible cracks, separation, powdering)

Related issues such as exhaust stress or hose/pipe rubbing due to excessive movement

Visual inspection: cracks, debonding, corrosion

Lever test (with safe support): check for abnormal movement

Road test comparison: symptoms concentrated on a certain side or RPM band

Workshops should check mounts together with transmission mount and related bushings to avoid replacing one part while the root cause remains.

Use reliable lifting equipment and a proper engine/transmission support tool

Never support directly under the oil pan without correct protection

Mark original position and any shims/limit structures to avoid misalignment

Relieve stress from related pipes/brackets if needed

Unload mount gradually; avoid removing bolts under load

Clean mating surfaces; inspect threads and seats

Install and tighten in stages to ensure natural stress-free alignment

Confirm engine alignment and no interference/pulling

Test at low-speed start/accel/decel and shifting conditions

Re-check fasteners per workshop procedure

Avoid repeated aggressive low-RPM high-torque launches

Fix oil leaks and overheating early (oil exposure accelerates aging for some compounds)

Inspect surrounding mounts to prevent overload and early failure of the new mount

As an original manufacturer of rubber-metal NVH components, Hebei Huami New Material provides stable mass production and validation capability for both heavy-duty trucks and passenger-car aftermarket:

30 years of rubber product & rubber-metal part manufacturing experience

Broad industries served: heavy-duty trucks, commercial vehicles, construction machinery, high-speed rail, aerospace

Quality systems & trade strength: IATF16949, TÜV certification, AEO Advanced Certification for reliable export delivery

In-house compound R&D: high damping, durable, heavy-duty reinforced mount solutions available

Precision molds & automated production: high batch consistency for distributors and fleet procurement

Full-process quality inspection: hardness / tensile / tear / compression set / bonding strength

Reliability validation: oil resistance, heat aging, salt spray, low/high temperature, fatigue life tests (per customer standards)

Flexible cooperation: OEM/ODM, small-batch customization, stable lead time

Choosing a reliable rubber metal engine mount supplier reduces warranty risk, improves batch consistency, and ensures long-term supply stability.

Note: The table below is for aftermarket identification and selection. Final fitment should be confirmed by drawing/sample and OEM data.

| Item | Specification / Notes |

|---|---|

| Product Name | Volvo Truck Engine Mount (Rubber-Metal Engine Mount) |

| OEM | 21416526 |

| Replacement / Equivalent OEM | 7421416526 |

| Rubber Material | NR / NBR / EPDM (compound customizable) |

| Hardness (Shore A) | 55–75 (customizable: comfort / heavy-duty / oil-resistant) |

| Metal Parts | High-strength steel; corrosion protection per specification |

| Typical Mounting Position | Engine side mount / front-rear support (depends on FH/FM/FMX layout) |

| Applications (Trucks) | Volvo FH / FM / FMX; RENAULT TRUCKS C / T / K |

| Applications (Passenger Cars) | DS 7 Crossback; DS 3 Convertible; CITROËN DS3 / C4 / C5; PEUGEOT 308 / 508 / 3008 / 5008 |

A: Yes, 7421416526 is commonly listed as a cross reference/replacement for 21416526 in aftermarket systems. Final confirmation should be made by checking dimensions, mounting points, and hardness.

A: Primary applications include Volvo FH, Volvo FM, and Volvo FMX. Fitment can vary by model year and mounting position—confirm with VIN or sample.

A: It is commonly listed as compatible with Renault Trucks C, T, and K in cross-reference catalogs. Confirm mounting geometry and spec for your application.

A: Cross-OEM catalogs may group parts by structural equivalence. Always verify dimensions, mounting design, limit stops, and hardness before using it on passenger cars.

A: Excessive idle vibration, harsher shifting/acceleration impacts, abnormal noises, engine sag/offset, and visible cracking or debonding.

A: Typical specification is 55–75 Shore A, depending on vehicle and duty cycle. Heavy-duty use favors stronger load control; comfort favors isolation. Custom tuning is available.

A: Common options include NR for dynamic damping, NBR for oil resistance, and EPDM for heat/ozone resistance. Compounds can be tailored for durability.

A: Bonding life depends on metal pretreatment, adhesive system, and stable vulcanization control. Bonding strength testing helps prevent debonding failure.

A: Yes. We support OEM/ODM based on drawings or samples, with flexible trial orders and stable mass production lead time.