A global supplier of specialty rubber seals and shock absorbers.

Strong manufacturing and R&D capabilities.

More than 30 years of R&D and manufacturing experience.

Views: 0 Author: Site Editor Publish Time: 12-06-2025 Origin: Site

In the steel leaf spring suspension of MAN TGA / TGX / TGS, the leaf spring bushing is pressed into the spring eye or rocker arm bore. Through the inner sleeve, rubber layer, and outer shell, it creates:

A flexible connection between the leaf spring and the frame/rocker arm

An elastic interface instead of metal-to-metal contact

A way to absorb road impacts and vibrations when the truck passes potholes, speed bumps, or runs at high speed

For any heavy truck suspension bushing, this flexible connection is fundamental to improving ride comfort and protecting the chassis structure.

Leaf springs not only carry the vehicle weight; they also help locate the axle.

The leaf spring bushing, through coordinated deformation of the rubber and metal sleeves, controls small movements of the axle in:

Longitudinal direction

Lateral direction

Rotational (twisting) direction

When the bushing is worn or delaminated, you may see:

Axle shifting forward/backward or sideways

Nose-diving during braking

A “floating” or “twisting” feeling when driving at high speed or fully loaded

A healthy MAN leaf spring bushing is therefore critical to keeping the axle where the chassis designer intended it to be.

The leaf spring, chassis brackets, and rocker arms are mostly metal parts. Without a proper bushing – or with a failed one – you will see:

Metal-to-metal contact, causing oversized bores and accelerated wear

Strong vibration transmitted directly to the chassis and cab

Higher fatigue on the driver during long working hours

Long-term negative impact on instrumentation, wiring, bodywork, and cargo body

A high-quality MAN leaf spring bushing significantly reduces these hidden costs and keeps the vehicle more comfortable and reliable in heavy-duty transport.

MAN TGA / TGX / TGS trucks are widely used in:

Long-haul logistics

Construction and engineering transport

Cold chain and container transport

Regional distribution and mixed road conditions

Typical operating conditions are:

Long periods at or near full load

High mileage and high-frequency vibration

Rough roads: national highways, ports, construction sites, mining areas, etc.

This imposes stringent requirements on the shear strength, compression performance, and fatigue life of the leaf spring bushing.

If you use a bushing designed for lighter vehicles, it may crack, tear, or delaminate in a short time. Choosing a true heavy truck suspension bushing specifically engineered for this environment is key to reducing downtime and total cost of ownership.

This bushing is mainly designed for:

MAN TGA series

MAN TGX series

MAN TGS series

It is used to replace the original OEM: 81437220070 leaf spring bushing, one of the common wear parts in the rear suspension of these heavy trucks.

On these models, the MAN leaf spring bushing 81437220070 is usually installed at:

The front and rear spring eyes of the leaf spring

Connection points between the leaf spring and rocker arm/equalizer

In some designs, as the pivot bushing for balance arms or rods connecting the axle to the frame

Exact positions should be confirmed with the vehicle VIN, parts catalog, and repair manual, but in all cases, this part functions as a pivot bushing in the leaf spring suspension system.

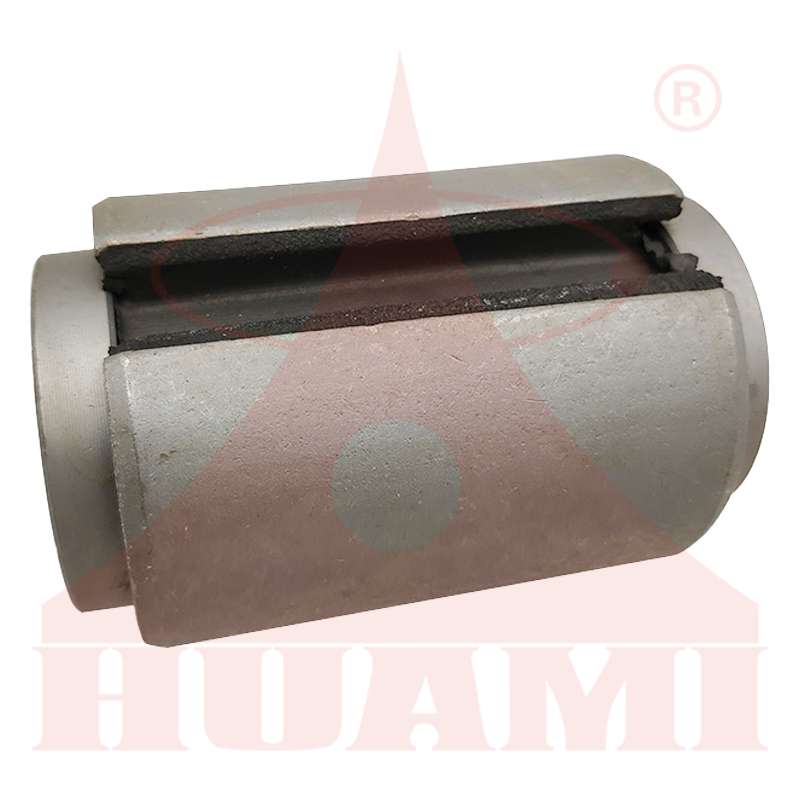

A standard MAN leaf spring bushing (OEM 81437220070) generally consists of three elements:

Inner sleeve

Steel machined part, matching the bolt or pin

Usually treated with phosphate and anti-rust oil for corrosion protection

Rubber layer

Bonded to the inner and outer sleeves through hot vulcanization

Determines the bushing’s stiffness, damping, displacement capacity, and fatigue life

Outer shell

Press-fitted into the leaf spring eye or rocker arm bore

Requires adequate strength and dimensional accuracy for stable fit

This rubber-metal leaf spring bushing design combines the load-carrying capacity of steel with the elasticity and damping of rubber, effectively absorbing vibration and shock.

Hebei Huami New Material selects the rubber compound according to operating conditions and customer requirements, for example:

NR/BR systems

Suitable for large deflection and high-frequency vibration

Excellent elasticity and fatigue resistance

NBR systems

Better resistance to oils, diesel, and lubricants

Suitable for oily and contaminated environments

EPDM systems

Excellent weather, ozone, and high/low temperature resistance

Suitable for vehicles exposed to harsh outdoor conditions

For typical MAN TGA / TGX / TGS long-haul applications, Huami uses high-damping heavy-duty compounds that balance comfort, durability, and cost.

To meet heavy truck suspension demands, the rubber hardness of the 81437220070 bushing is usually designed in the range:

Shore A 65–80 (typical range)

Can be tuned according to fleet operating conditions (mining, extreme cold, port operations, etc.)

Key performance indicators include:

Abrasion resistance – to prevent rubber chunking or excessive wear

Compression set resistance – to retain shape and elasticity after long-term compression

Fatigue resistance – to withstand millions of cycles of shear, compression, and torsion without crack growth

In service, the bushing is subject to:

Axial compression

Radial shear

Torsional deformation

Hebei Huami New Material uses finite element analysis (FEA) and durability bench testing to optimize:

Rubber geometry and thickness

Metal sleeve design

Compound formulation

The result is a bushing that:

Provides appropriate movement and comfort under normal loads

Resists tearing or delamination under peak or shock loads

Maintains stable stiffness over high mileage and harsh cycles

To withstand salt spray, mud, and winter road conditions, the inner and outer sleeves usually receive:

Anti-corrosion coating or plating

Additional pre-treatment such as phosphating or shot blasting if needed

Rubber and metal are bonded using a professional adhesion system and controlled vulcanization process, effectively preventing:

Relative slip between inner and outer sleeves

Debonding at the rubber-metal interface

Early delamination failures in heavy-duty service

In real-world use, the following issues are frequently searched and asked by fleets and workshops.

Typical symptoms:

“Creaking” or “squeaking” sounds when passing bumps or ramps

Slight but noticeable cab vibration at speed

Possible causes:

Aged and hardened rubber layer

Excessive clearance between inner sleeve and bolt

Outer shell turning or loosening in the leaf spring eye or rocker arm bore

Visual inspection may reveal:

Rubber worn more on one side, or clearly twisted

Cracks on the rubber surface (longitudinal or transverse)

Visible opening or peeling between rubber and metal edges

This indicates that the heavy truck suspension bushing is close to or at the end of its service life and should be replaced soon.

Symptoms include:

Steering wheel needs constant correction when driving straight

Abnormal or uneven tire wear

Vehicle “pulls” to one side under braking

Besides checking front axle alignment and tires, inspect the leaf spring bushings. Worn bushings can cause axle position changes, leading to these issues.

Before MAN TGA bushing replacement, fleets and workshops can use the following steps:

Lift the vehicle or park it over a pit

Ensure safe access to the suspension components

Visual inspection

Check bushings at spring eyes and rocker arms for cracks, delamination, eccentric wear, or missing rubber pieces

Lever test

Use a pry bar near the leaf spring end or rocker arm

If there is obvious free play, excessive movement, or a “clicking” sound at the bushing, it is likely worn out

Measure clearance (for higher standards)

Use feeler gauges or dial indicators to measure gaps or displacement

Compare results with workshop or OEM guidelines

Combine with mileage

For high-mileage long-haul trucks, a full suspension inspection is recommended every 200,000–300,000 km, with preventive replacement if necessary

Remove the leaf spring or rocker arm assembly

Secure the vehicle, apply the parking brake, and follow safety procedures

Mark positions and orientation of parts for correct reassembly

Remove the old bushing

Use a hydraulic press or dedicated puller to push the old bushing out

Avoid burning or heavy hammering, which can damage the spring eye or rocker arm bore

Clean and inspect the bore

Remove rust and debris from the bore

Check for ovality or oversize; repair or replace components if the bore is seriously out of round

Press in the new bushing

Confirm that the bushing matches OEM: 81437220070 and is free of damage

Apply appropriate lubricant if allowed by the manufacturer

Use proper fixtures to ensure the bushing is aligned with the bore and press it in slowly and evenly

Reinstall the assembly

Refit the leaf spring or rocker arm according to alignment marks

Pre-tighten bolts without fully torquing them yet

Some leaf spring bushings may have a specific orientation (eccentric design or asymmetric flanges). Always follow the MAN factory service manual and diagrams.

Ensure that the outer shell’s projection on each side of the spring eye or rocker arm shoulder is within the specified range and not offset.

Avoid long-term severe overload

Clean mud and corrosive substances around the suspension regularly

Replace bushings as soon as early cracks or hardening are found to prevent damage to spring eyes, brackets, and rocker arms

Use high-quality MAN leaf spring bushing 81437220070 from reliable manufacturers to reduce early failures

Heavy-Duty Rubber-Metal Bushing Specialist

Hebei Huami New Material Technology Co., Ltd. has been specialized in rubber compounds and rubber products for decades and offers strong capabilities in heavy truck suspension bushings.

Founded in the late 1990s, Huami has focused on special rubber compounds and rubber parts for automotive, construction machinery, rail, petroleum equipment, and other industries

Hundreds of employees and dozens of authorized patents

Participation in the drafting of several national and industry standards

This long industrial experience provides a solid foundation for the development and production of heavy truck suspension bushings.

Huami has:

IATF 16949 automotive quality management system

ISO 9001, ISO 14001, ISO 45001 and other management systems

AEO Advanced Certification for customs, as well as TÜV-related certifications

For global fleets and distributors, this means:

Traceable quality

Stable and consistent product performance

More efficient cross-border logistics and customs clearance

For harsh applications such as mining, ports, oilfields, and cold chain, Huami can provide:

High-damping compounds to improve vibration isolation

Rubber formulations with enhanced abrasion and fatigue resistance

Thicker rubber sections or reinforced structural designs to increase life beyond OE specification where needed

This is especially valuable for fleets seeking longer replacement intervals than standard OEM parts.

In-house tool design and manufacturing with CNC machining centers

Tight control of inner and outer diameter and rubber thickness

Statistical Process Control (SPC) and in-line inspection to keep batch-to-batch variation very low

This dimensional consistency leads to easier pressing, fewer noises after installation, and more predictable behavior across large fleets.

Huami’s laboratory can perform:

Rubber hardness, tensile strength, and tear strength tests

Compression set, rubber-metal bonding strength, abrasion tests

Salt spray, oil resistance, high/low temperature tests

Heavy-duty fatigue tests simulating real road conditions

From raw materials to finished leaf spring bushings, every stage is validated to ensure that MAN 81437220070 leaf spring bushings perform reliably in actual service.

Support for sample development, small pilot batches, and large-scale production

Adaptable to OEM projects, aftermarket distribution, and direct fleet supply

With the AEO Advanced Certification advantage, Huami provides stable lead times and smooth export processes

For international distributors and large fleets, this translates into better supply security and lower inventory risk.

The table below is a web display template. Please fill in exact dimensions and data according to drawings and measurements.

| Item | Example / Placeholder | Description |

|---|---|---|

| Product Name | MAN Leaf Spring Bushing | Leaf spring rubber-metal bushing |

| OEM Number | 81437220070 | Matches MAN OE reference |

| Vehicle Models | MAN TGA / MAN TGX / MAN TGS | Rear suspension |

| Rubber Material | NR / BR / NBR / EPDM (customizable) | Heavy-duty high-damping compound |

| Rubber Hardness (Shore A) | 65–80 (customizable) | Typical range; final spec per order |

| Metal Sleeves | Quality carbon steel or alloy steel | With anti-corrosion surface treatment |

| Installation Position | Rear leaf spring / rocker arm connection | Pivot points in the leaf spring suspension |

| Application | Heavy truck suspension bushing | Full-load, high-mileage, high-vibration conditions |

| Country of Origin | China - Hebei Huami New Material | Manufacturer information |

| Packing | Neutral carton / pallet (customizable) | As per customer requirement |

Q1: What is the typical service life of MAN leaf spring bushing OEM 81437220070?

A: Under normal road conditions and regular maintenance, the 81437220070 leaf spring bushing on MAN TGA, TGX, and TGS trucks can usually run 200,000–400,000 km. For severe applications such as mining or off-road use, inspections and MAN TGA bushing replacement should be carried out more frequently.

Q2: What are the common symptoms that indicate the MAN leaf spring bushing needs replacement?

A: Typical symptoms include knocking or creaking noises from the spring area, increased cab vibration, vehicle pulling or unstable braking, and visible cracks, rubber peeling, or eccentric wear on the bushing. Any of these signs mean the bushing should be inspected and replaced in time.

Q3: Can a universal heavy truck suspension bushing be used instead of OEM 81437220070?

A: It is not recommended. Even if the size looks similar, a universal heavy truck suspension bushing may affect axle alignment, noise level, and durability. Always select parts that match OEM 81437220070 or verified cross reference numbers.

Q4: What should I pay attention to during MAN TGA bushing replacement?

A: Use a proper press tool, do not burn or hammer the bushing violently, clean the spring eye or rocker arm bore thoroughly, align the bushing correctly, and tighten bolts with the truck on its wheels at normal ride height, using the specified torque values.

Q5: What are the advantages of Hebei Huami New Material MAN leaf spring bushings?

A: Hebei Huami New Material uses heavy-duty rubber compounds, high-precision tooling, and full laboratory testing (hardness, tensile, adhesion, fatigue, etc.) to provide long life and stable performance for MAN heavy truck suspension systems. Customized and reinforced versions are also available for harsher conditions.

Q6: Can the hardness of MAN leaf spring bushing 81437220070 be customized?

A: Yes. Within a reasonable Shore A range, Hebei Huami New Material can adjust rubber hardness and compound formulation for different applications such as mining, cold chain, or port logistics, balancing comfort and durability.

Q7: How can logistics fleets reduce the overall cost of their leaf spring bushings?

A: Choose high-quality bushings, establish mileage- and condition-based inspection schedules, avoid prolonged overloading and aggressive driving, and work with suppliers who are certified (IATF 16949, TÜV, AEO Advanced Certification) and experienced in heavy truck suspension bushings.

Q8: Does Hebei Huami New Material support samples and small batch trial orders?

A: Yes. The company can develop and supply samples and small batches of MAN 81437220070 leaf spring bushings based on drawings or original samples, then scale up to mass production with stable lead times and technical support during field trials.

Scania Truck Suspension Rubber Bushing OEM:1919010 Technical Guide

Mack Truck Cab Mount Bracket OEM 20975430: In-Depth Guide & Selection Tips

MAN Truck Engine Mount OEM 81962100571: Function, Materials, Failure Signs & Replacement Guide

DAF Truck Cab Support Bushing OEM:1911932 Selection, Structure & Replacement Guide